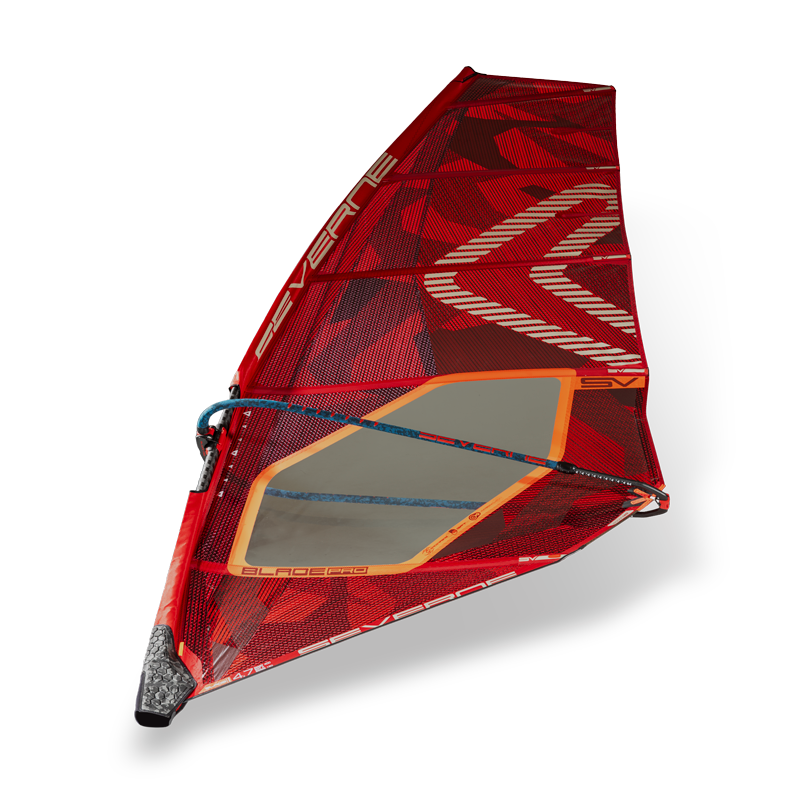

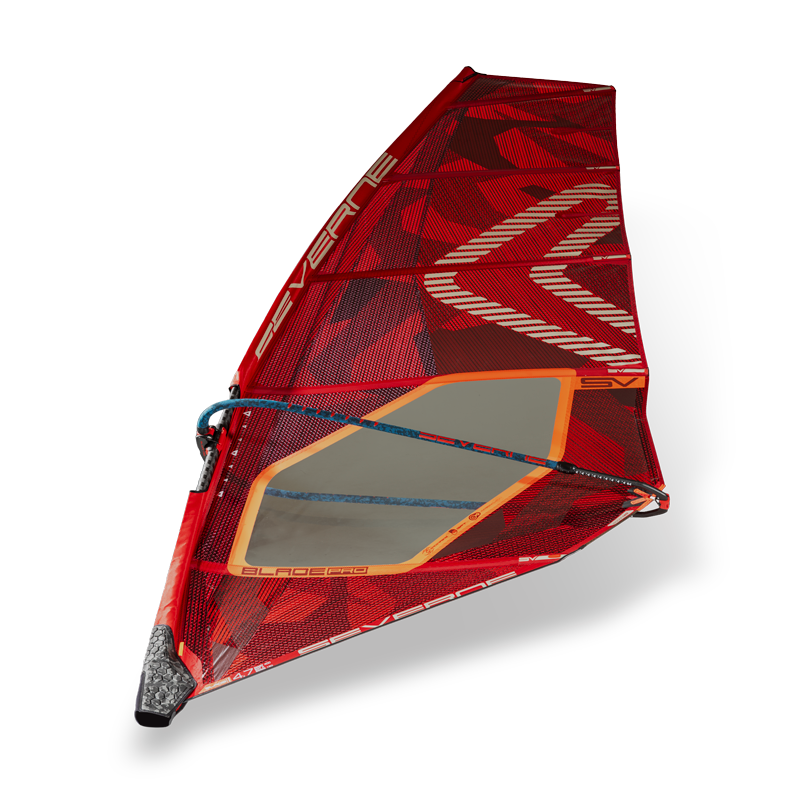

BLADE PRO_PREMIUM CONTROL

The Blade has defined the 5-batten wave sail category for 20 years. The latest 024 incarnation continues to refine and polish this proven performer.

Delivering dependable performance across the widest possible wind range. A perfect blend of power and control.

Both Blade and BladePro have been developed on an identical platform. The PRO construction offers the ultimate experience while the Blade replicates the dynamic performance in a more accessible construction.

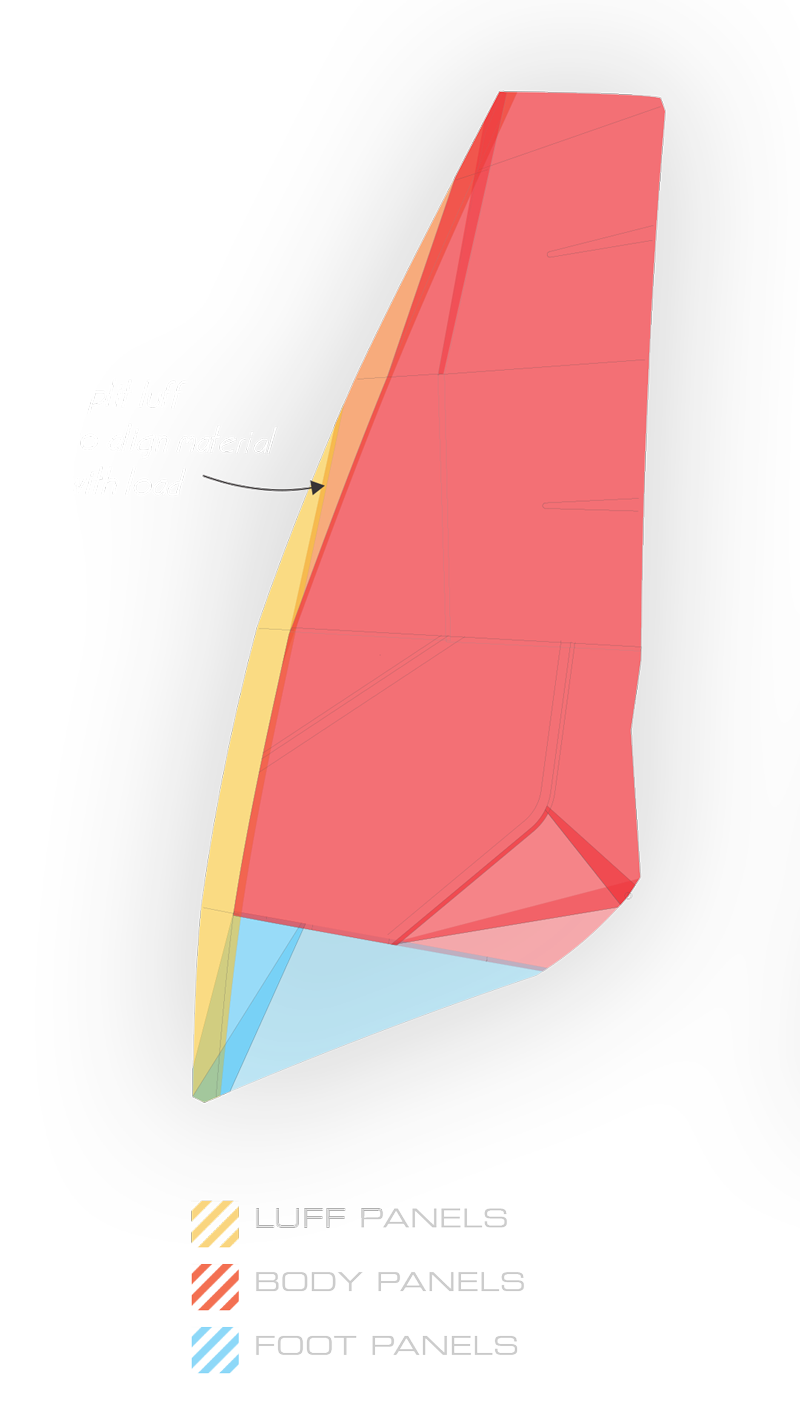

Both constructions utilize GRADIENT PANEL TECHNOLOGY to logically reduce weight, increase strength, and control stretch. Direct transmission of power. Increased longevity.

The Blade features quality materials including VX2, SpiderFibre, and eM4. The BladePro is crafted in CARBON FUSION.

Total Control. The Blade is the control-oriented wave sail for any conditions.

/ 5 BATTEN DESIGN

/ 100% X-PLY

/ DEVELOPED WITH SCOTT MCKERCHER AND PHILIP KOSTER

SIZES 3.0 / 3.3 / 3.5 / 3.7 / 4.0 / 4.2 / 4.5 / 4.7 / 5.0 / 5.3 / 5.5 / 5.7 / 6.2 / 6.7

BLADE PRO_PREMIUM CONTROL

The Blade has defined the 5-batten wave sail category for 20 years. The latest 024 incarnation continues to refine and polish this proven performer.

Delivering dependable performance across the widest possible wind range. A perfect blend of power and control.

Both Blade and BladePro have been developed on an identical platform. The PRO construction offers the ultimate experience while the Blade replicates the dynamic performance in a more accessible construction.

Both constructions utilize GRADIENT PANEL TECHNOLOGY to logically reduce weight, increase strength, and control stretch. Direct transmission of power. Increased longevity.

The Blade features quality materials including VX2, SpiderFibre, and eM4. The BladePro is crafted in CARBON FUSION.

Total Control. The Blade is the control-oriented wave sail for any conditions.

/ 5 BATTEN DESIGN

/ 100% X-PLY

/ DEVELOPED WITH SCOTT MCKERCHER AND PHILIP KOSTER

SIZES 3.0 / 3.3 / 3.5 / 3.7 / 4.0 / 4.2 / 4.5 / 4.7 / 5.0 / 5.3 / 5.5 / 5.7 / 6.2 / 6.7

| 024 Blade Pro | Luff | Boom | Battens | Weight | Head | Recommended Mast | Alternative Mast | Recommended Boom | Alternative Boom | Extension |

|---|---|---|---|---|---|---|---|---|---|---|

| 3.0 | 344 | 140 | 5 | 2.1 | ADJ 11CM | RDM BLUE 340 | GORILLA 340 | Enigma 140 | METAL 140 | Cyclops 24 |

| 3.3 | 341 | 141 | 5 | 2.09 | FIXED | RDM BLUE 340 | GORILLA 340 | Enigma 140 | METAL 140 | Cyclops 24 |

| 3.5 | 352 | 146 | 5 | 2.19 | FIXED | RDM BLUE 340 | GORILLA 340 | Enigma 140 | METAL 140 | Cyclops 24 |

| 3.7 | 369 | 148 | 5 | 2.3 | FIXED | RDM BLUE 340 | GORILLA 340 | Enigma 140 | METAL 140 | Cyclops 36 |

| 4.0 | 376 | 150 | 5 | 2.39 | FIXED | RDM RED 370 | RDM BLUE/GORILLA 370 | Enigma 140 | METAL 140 | Cyclops 24 |

| 4.2 | 385 | 154 | 5 | 2.44 | FIXED | RDM RED 370 | RDM BLUE/GORILLA 370 | Enigma 140 | METAL 140 | Cyclops 24 |

| 4.5 | 404 | 157 | 5 | 2.54 | FIXED | RDM RED 370 | RDM BLUE/GORILLA 370 | Enigma 140 | METAL 140 | Cyclops 36 |

| 4.7 | 406 | 160 | 5 | 2.63 | FIXED | RDM RED 400 | RDM BLUE/GORILLA 400 | Enigma 150 | METAL 150 | Cyclops 24 |

| 5.0 | 414 | 164 | 5 | 2.72 | FIXED | RDM RED 400 | RDM BLUE/GORILLA 400 | Enigma 150 | METAL 150 | Cyclops 24 |

| 5.3 | 423 | 168 | 5 | 2.85 | FIXED | RDM RED 400 | RDM BLUE/GORILLA 400 | Enigma 150 | METAL 150 | Cyclops 24 |

| 5.5 | 429 | 170 | 5 | 2.92 | FIXED | RDM RED 400 | RDM BLUE/GORILLA 400 | Enigma 150 | METAL 150 | Cyclops 36 |

| 5.7 | 433 | 171 | 5 | 2.96 | FIXED | RDM RED 430 | RDM BLUE/GORILLA 430 | Enigma 150 | METAL 150 | Cyclops 24 |

| 6.2 | 455 | 174 | 5 | 3.16 | FIXED | RDM RED 430 | RDM BLUE/GORILLA 430 | Enigma 150 | METAL 150 | Cyclops 36 |

| 6.7 | 462 | 183 | 5 | 3.28 | FIXED | RDM RED 460 | RDM BLUE/GORILLA 460 | Enigma 150 | METAL 150 | Cyclops 24 |

TECHNOLOGY

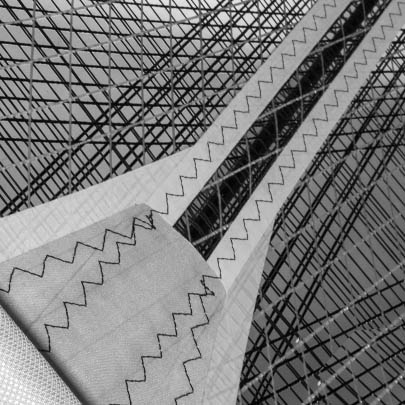

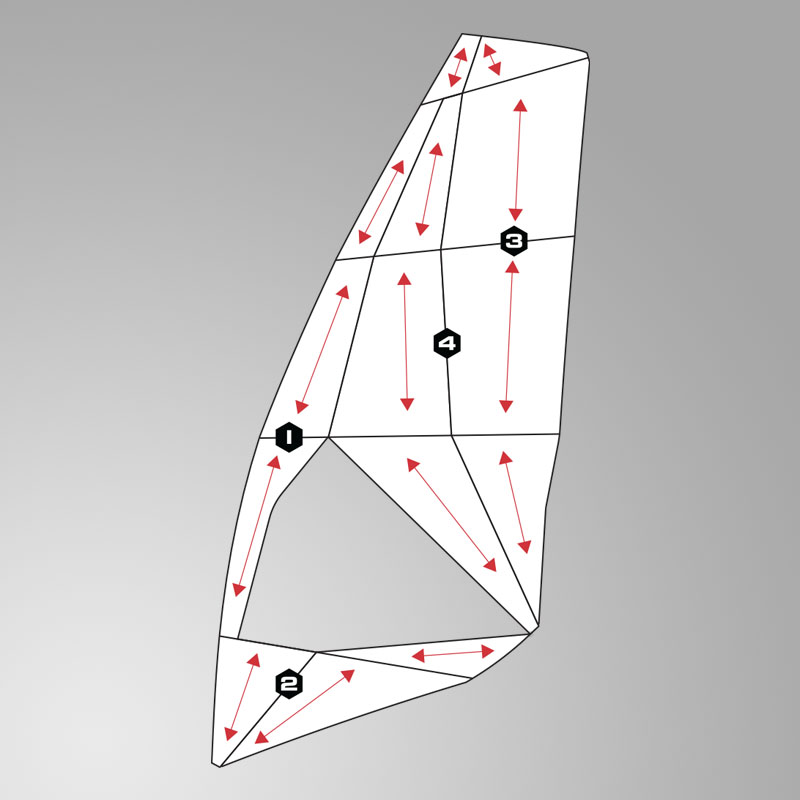

GRADIENT PANEL TECHNOLOGY

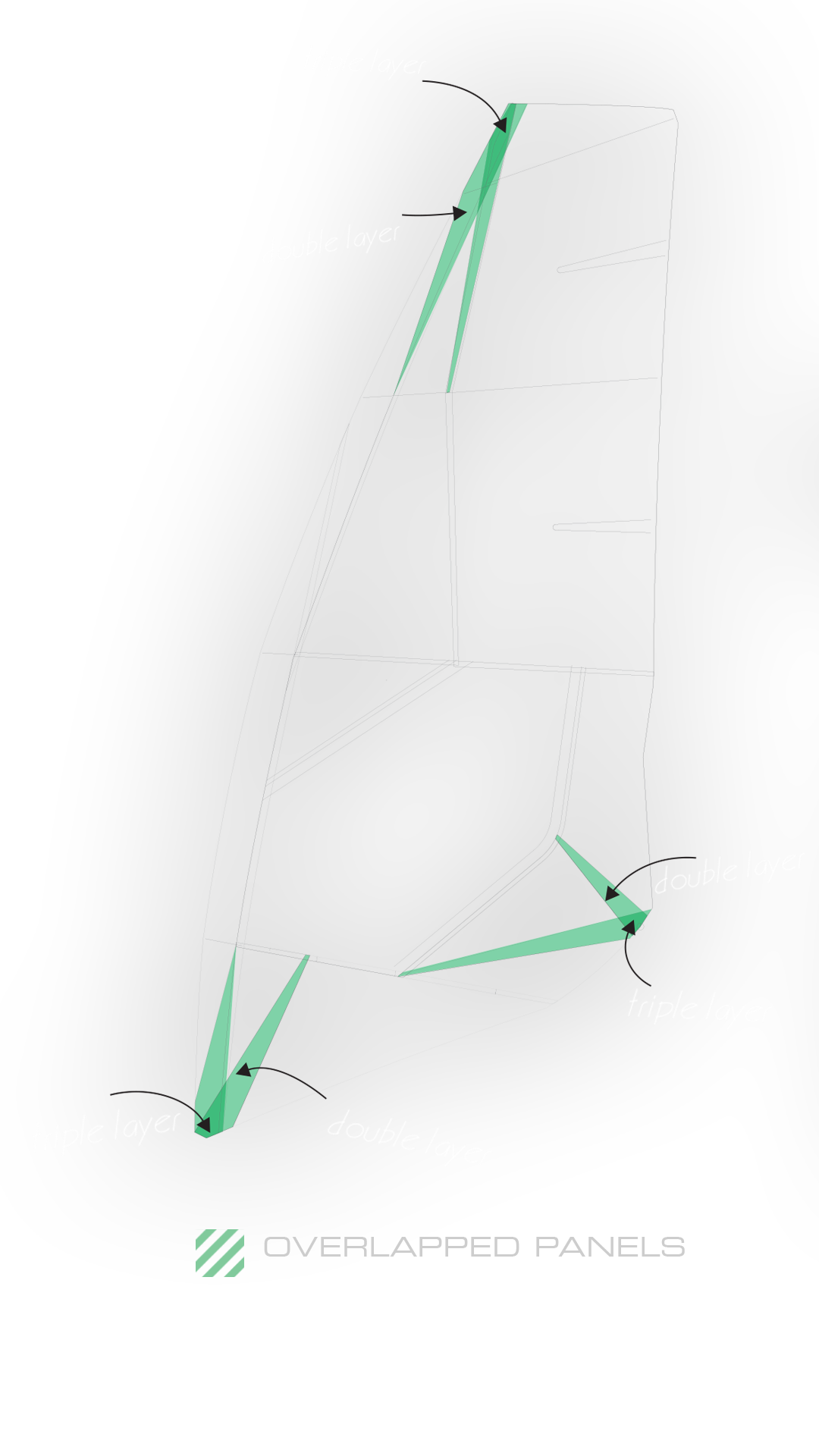

The Blade Pro uses the new GRADIENT PANEL TECHNOLOGY. Corners have overlapped panels which reduces the amount of patching. At the same time these overlapped areas extend into the body of the sail so it transitions the load much better, will be less stretch over time. It’s a more stable way of building sails.

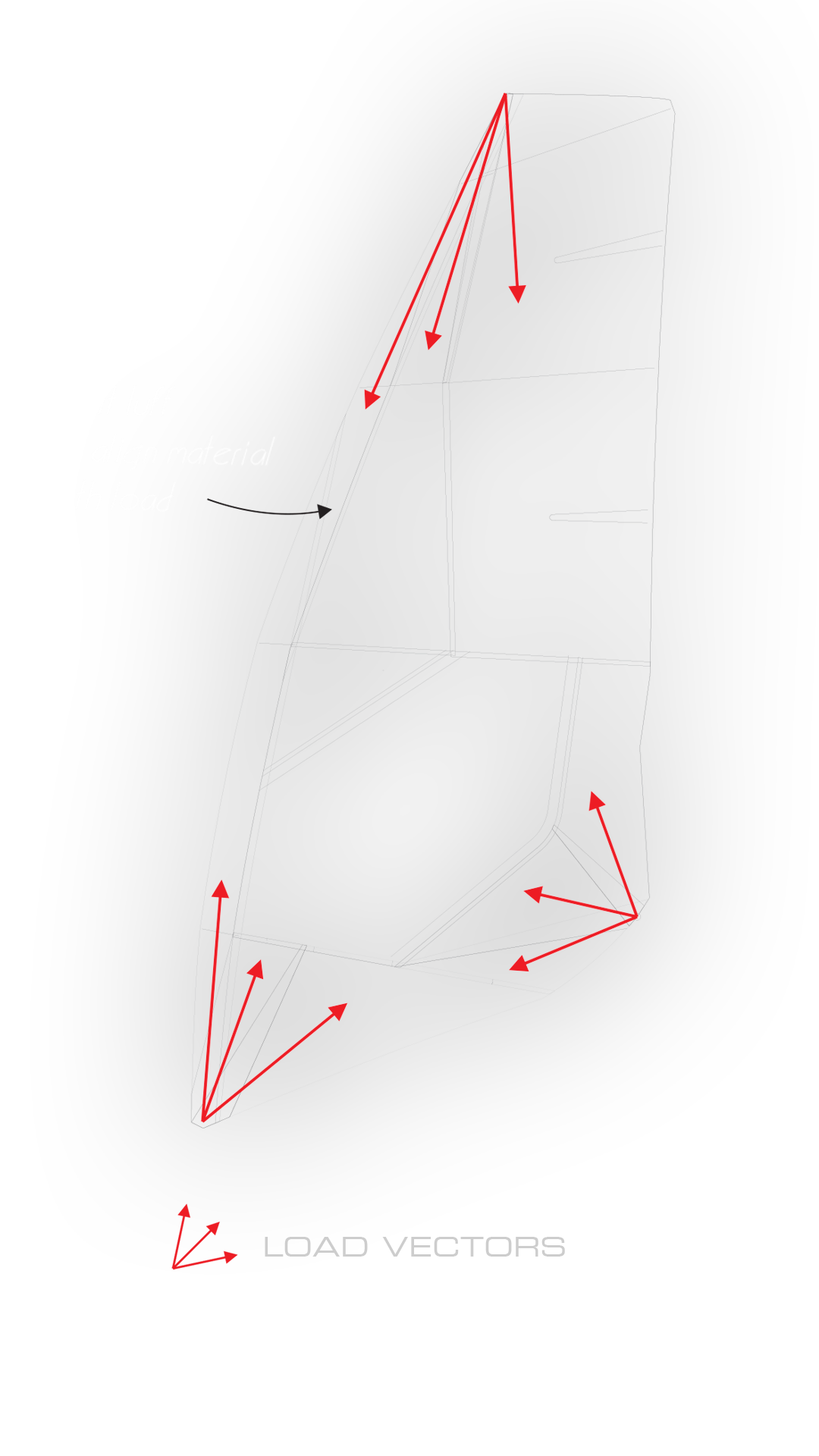

Rather than a single curved luff panel, the Blade Pro uses separate panels that radiate out of the head and tack corners. This perfectly aligns the sail material with the direction of load. Previously the curved panel would have bias stretch in all the wrong places. Direct transmission of power. Increased longevity. Total Control.

AERO BATTEN TECHNOLOGY

In our quest to create a truly symmetrical sail we have developed the AERO BATTEN POCKET. Rather than add the batten pocket on one side of the sail, the panels of the sail are overlapped to create a channel for the batten. The tensioner is then loaded from both sides of the sail creating even tension across both sides of the foil.

The result is improved sail symmetry and reduced weight.

CARBON FUSION TECHNOLOGY

PRECISE. ALIVE. ELECTRIC

Our search for higher performance has brought us CarbonFusion, the next level in load-path sail construction.

Carbon Fusion sails are composed of 3 key components;

/ MATERIAL

/ FUSED SEAMS

/ LOAD PATH FRAME

The result of these 3 key components effectively turns the sail into a spring. Load it up, and release for explosive performance.

GRADIENT PANEL TECHNOLOGY

With the new GRADIENT PANEL TECHNOLOGY improvements are obvious. Lighter weight and better stability.

Using the new GRADIENT PANEL TECHNOLOGY. Corners have overlapped panels which reduces the amount of patching. At the same time these overlapped areas extend into the body of the sail so it transitions the load much better, will be less stretch over time. It’s a more stable way of building sails.

The GRADIENT PANEL TECHNOLOGY logically reduces weight, increases strength and controls stretch. Overall weight is reduced but the more significant improvement is the feel – quicker reacting and lighter feel.

Rather than a single curved luff panel, we use separate panels – split luff – that radiate out of the head and tack corners. This perfectly aligns the sail material with the direction of load.

Previously the curved panel would have bias stretch in all the wrong places. Direct transmission of power. Increased longevity.

RECOMMENDED

/ BOARD

PYRO

NANO

PROJECT SCOTT

/ MAST

RDM RED – For ultimate performance.

RDM BLUE – High-end performance with increased reliability.

BLADE PRO is recommended for RDM masts.

/ BOOM

ENIGMA – For ultimate performance.

/ EXTENSION

CYCLOPS

COMPARISON

/ S-I PRO

The BLADE PRO has 5 battens.

The BLADE PRO drives power down through the board for maximum control.

/ BLADE

The BLADE PRO features CarbonFusion technology.

The BLADE PRO is lighter.

What changed from 023 to 024 Blade Pro?

024 Blade Pro sails are constructed using CarbonFusion, and no longer make use of HyperSpider membrane technology.

You can read more about CarbonFusion by clicking this link.

What is the difference between the Blade and the Blade Pro?

The key difference between the Blade and Blade Pro is the material, as well as, the construction.

Blade Pro is the only sail that is built using carbon fibre laminates from head to tack. Carbon is a higher-performance fibre than the Technora, Kevlar, or polyester used in all other sails.

Better strength-to-weight ratios, more reactive, wider wind ranges.

The Blade Pro features Carbon Fusion

The Blade Pro uses carbon fibre laminate from head to tack

The Blade Pro is more reactive

The Blade Pro features a better strenght to weight ratios

Can I rig the Blade Pro on a SDM mast?

No, the Blade Pro is designed for RDM masts.

WHAT IS THE DIFFERENCE BETWEEN THE BLADE/BLADE PRO AND S-1?

The S-1 is a manouvrable oriented sail, meaning it has more backhand drive, allowing you to effortlessly change lines during your turns, wave 360, or aerial setup.

The Blade is kept neutral in the front of the sail to give a lot more control when riding or jumping.

The S-1 has 4 battens.

The S-1 is more manoeuvre oriented.

The S-1 has more backhand pressure.

The BLADE has 5 battens

The BLADE is more control oriented.

The BLADE is more stable.

The BLADE is full X-PLY

WHAT IS THE DIFFERENCE BETWEEN THE BLADE/BLADE PRO AND GATOR?

The Blade/Blade Pro is wave orientated whereas the Gator is a freewave/freeride oriented crossover sail.

The Blade/Blade Pro is specifically designed for the windsurfers who spend most of their time in the waves. A neutral sail that helps to improve riding and jumping.

The Gator will be your best match if you enjoy bump and jump conditions, occasionally riding some waves. Offering a softer, easier handling, the Gator will have you planning earlier than anyone else.

The Gator is freewave/freeride oriented.

The Gator planes earlier.

The Gator has five battens up to 7.0 and six battens from 7.5 and up.

The Blade is more wave oriented.

The Blade is more stable.

The Blade is more manoeuvreable.

The Blade is less freemove/freeride oriented

IS IT POSSIBLE TO GET CARBONFUSION AND OTHER REPAIR MATERIALS?

Yes, you can order repair material from your local dealer or distributor.

Use the dealer locator to find your nearest SEVERNE dealer.

HOW DO I RIG MY BLADE/BLADE PRO?

Check out our rigging guides section: https://www.severnesails.com/product-care/rigging-guides/

Can I rig the Blade Pro on a non-Severne mast?

All of our development, testing, rigging, and tuning are done using SEVERNE masts.

We strongly recommend our customers use SEVERNE masts. Our masts are designed with a specific SEVERNE bend curve that remains one of the pillars of our rigs.

We don’t test the performance or bend curves of other masts, and can thus not guarantee which performance or durability you can get out of your sail using a different brand mast.

We describe the curve of our mast as a SEVERNE curve.

The constant, hardtop, or flex top curves that generic mast brands describe base themselves on measurements on 3 points.

We measure our masts at 7 points minimum.