CARBON FUSION

PRECISE. ALIVE. ELECTRIC

Our search for higher performance has brought us CarbonFusion, the next level in load-path sail construction.

Carbon Fusion sails are composed of 3 key componants;

/ MATERIAL

/ FUSED SEAMS

/ LOAD PATH FRAME

The result of these 3 key components effectively turns the sail into a spring. Load it up, and release for explosive performance.

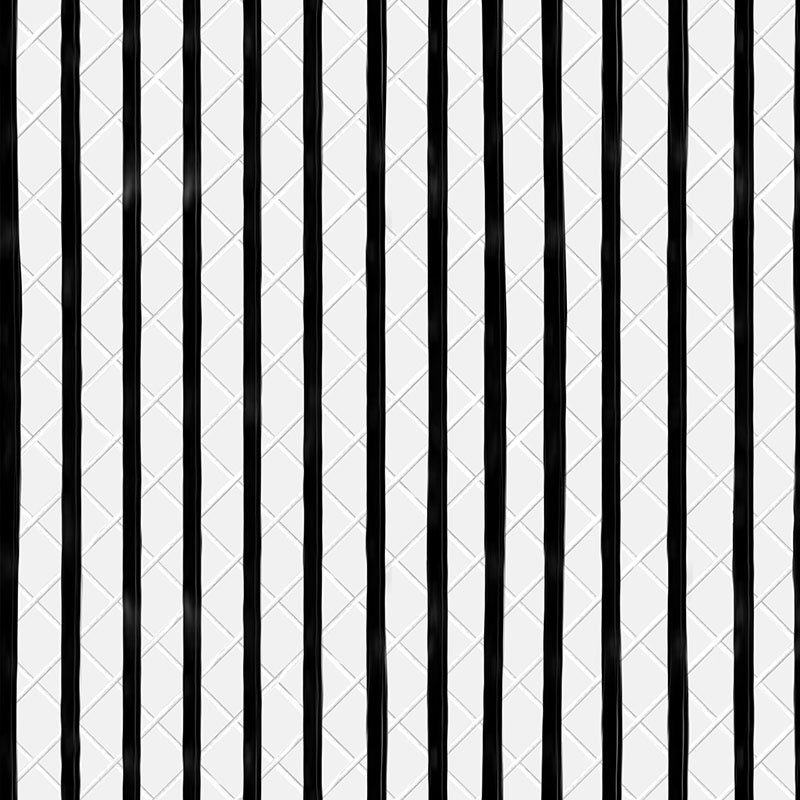

MATERIAL

UNIDIRECTIONAL CARBON FIBRE + OFF AXIS DYNEEMA.

Unidirectional Carbon is aligned to all primary load paths and eliminates any stretch. Off axis Dyneema enables horizontal elasticity, allowing the sail to flex and react with lightning speed. Superior fibres deliver superior performance;

/ DYNAMIC: Carbon warp with no stretch combined with medium stretch 45∞ Dyneema.

/ STRONGER: Dyneema is one of the strongest fibres available.

/ LIGHTER: Carbon has the highest strength to weight ratio.

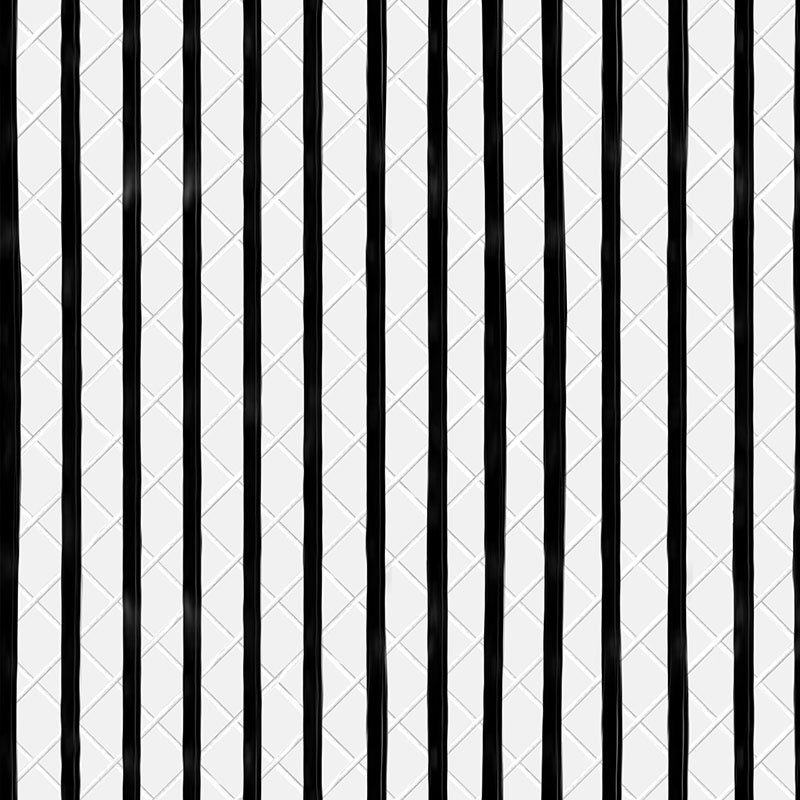

MATERIAL

UNIDIRECTIONAL CARBON FIBRE + OFF AXIS DYNEEMA.

Unidirectional Carbon is aligned to all primary load paths and eliminates any stretch. Off axis Dyneema enables horizontal elasticity, allowing the sail to flex and react with lightning speed. Superior fibres deliver superior performance;

/ DYNAMIC: Carbon warp with no stretch combined with medium stretch 45∞ Dyneema.

/ STRONGER: Dyneema is one of the strongest fibres available.

/ LIGHTER: Carbon has the highest strength to weight ratio.

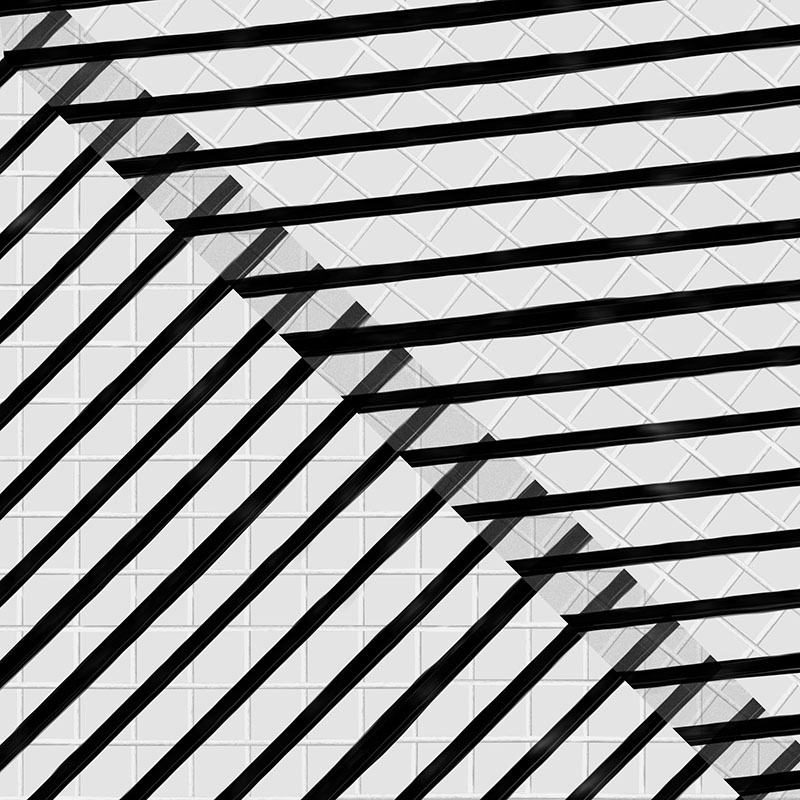

FUSED SEAMS

ULTRASONICALLY WELDED SEAMS.

Each carbon segment is ultrasonically welded in place. This has multiple advantages over traditional sewing techniques;

/ STRONGER: Full seam adhesion plus the benefit of not puncturing the films with needle holes.

/ LIGHTER: Removal of outer seam tapes and thread.

/ ACCURATE: No seam shrinkage from outer tapes, or thread tension.

FUSED SEAMS

ULTRASONICALLY WELDED SEAMS.

Each carbon segment is ultrasonically welded in place. This has multiple advantages over traditional sewing techniques;

/ STRONGER: Full seam adhesion plus the benefit of not puncturing the films with needle holes.

/ LIGHTER: Removal of outer seam tapes and thread.

/ ACCURATE: No seam shrinkage from outer tapes, or thread tension.

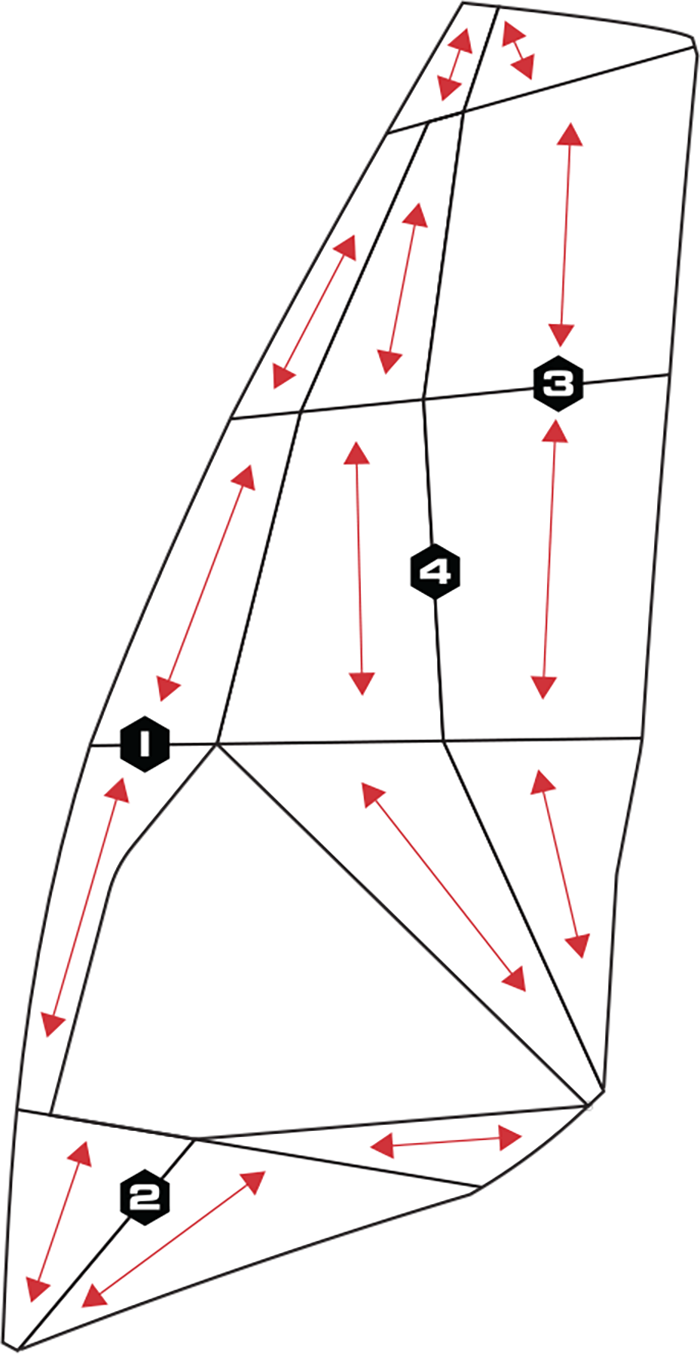

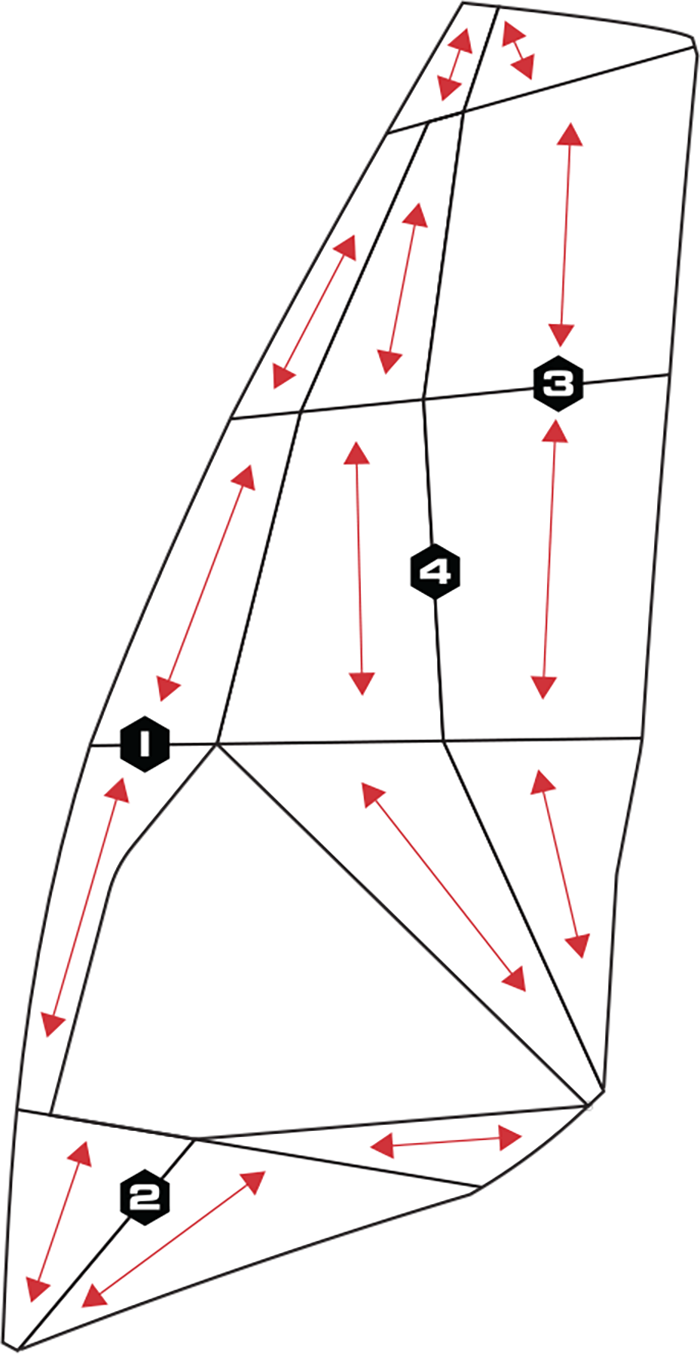

LOAD PATH FRAME

PANEL LAYOUT ALIGNED TO LOAD PATHS.

Each panel is strategically placed to align with the sails specific loads, on all sizes.

This has multiple advantages over aesthetic panel layouts;

/ LIGHTER: Aligning fibre accurately with the loads in the sail allows thinner films and much lighter sails.

/ STRONGER: High density of Dyneema and carbon in specific areas.

/ LIGHTNING RESPONSE: Carbon fibre transfers load instantly, without lag due to stretch.

1. PRIMARY LOADS

Primary loads run vertically between head and tack. Downhaul tension transfers directly through the warp oriented carbon.

2. FOOT LOADS.

Foot tensions transfer between the tack and the clew. High density fibreadds impact strength in this area.

3. LEECH LOADS

Leech loads run vertically up the leech, with dynamic loads tensioning the carbon and then springing back for explosive performance.

4. BODY LOADS

Body tension is transferred out of the head and clew.

LOAD PATH FRAME

PANEL LAYOUT ALIGNED TO LOAD PATHS.

Each panel is strategically placed to align with the sails specific loads, on all sizes.

This has multiple advantages over aesthetic panel layouts;

/ LIGHTER: Aligning fibre accurately with the loads in the sail allows thinner films and much lighter sails.

/ STRONGER: High density of Dyneema and carbon in specific areas.

/ LIGHTNING RESPONSE: Carbon fibre transfers load instantly, without lag due to stretch.

1. PRIMARY LOADS

Primary loads run vertically between head and tack. Downhaul tension transfers directly through the warp oriented carbon.

2. FOOT LOADS.

Foot tensions transfer between the tack and the clew. High density fibreadds impact strength in this area.

3. LEECH LOADS

Leech loads run vertically up the leech, with dynamic loads tensioning the carbon and then springing back for explosive performance.

4. BODY LOADS

Body tension is transferred out of the head and clew.