Severne EM3 & EM4 laminate technology

Severne develops its own proprietary materials where necessary. The em3 laminate technology was first developed in 2007 and has since evolved to em4 and other technologies.

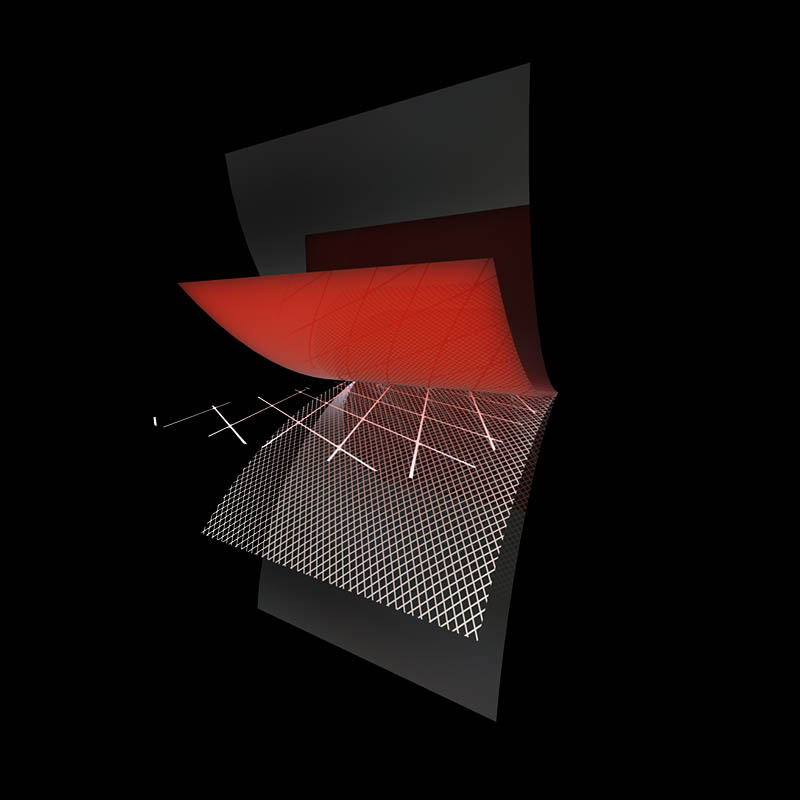

eM3: DURABLE AND LIGHTWEIGHT

Combining the performance of the e-series materials with maximum durability. The addition of a pre-preg polyester scrim has provided unique tear resistant characteristics.

Off-axis loads are carried through the 22-degree X-ply fibres. The red and new blue adhesive maintain the UV resistance and tear strength, while the reduced film thickness significantly reduces the weight.

The use in the upper panels reduces not only the overall sail weight, but also the swing weight, aiding manoeuvrability and control.

/ SCRIM: POLYESTER

/ X-PLY: POLYESTER

/ GSM: I60GSM

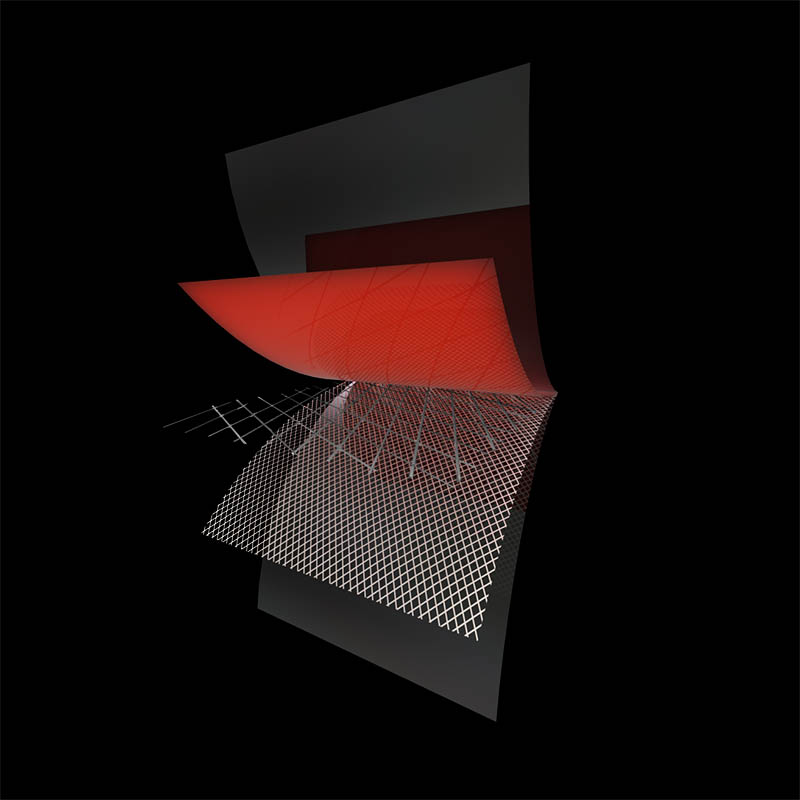

eM4: HIGH LOAD LAMINATE

Based on the proven eM3 platform, the high load eM4 material features twice the amount of X-Ply fibre and increased film thickness to maximise durability. This new material allows weight reduction whilst maintaining puncture resistance and tear strength. Used in the lower impact zone in the sail.

/ SCRIM: POLYESTER

/ X-PLY: POLYESTER x 2

/ GSM: 190GSM